Predix Manufacturing Execution Systems

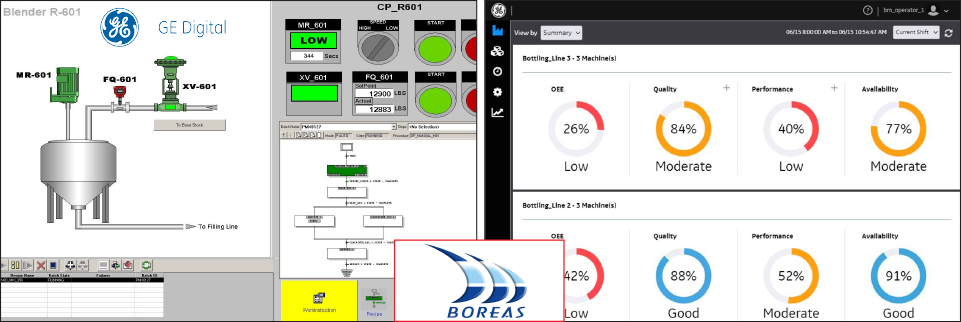

Plant Applications, part of the Predix Manufacturing Execution Systems (Predix MES) suite of solutions, is a powerful operations management solution for process manufacturers, such as Food and Beverage (F&B) and Consumer Packaged Goods (CPG), that collects and analyzes data, and helps manage highly automated fast-moving processes.

Also, it automates and integrates the information-related activities for managing production execution and performance optimization holistically, helping to balance the tradeoffs between competing priorities of production operations.

Efficiency management

Track and monitor OEE and other critical key performance indicators (KPIs)—downtime, waste, and production counts, mean time between failure (MTBF), mean time to repair (MTTR), and more. Correlate events and reasons to production parameters to identify root causes. Utilize standard and ad-hoc reports for real-time decision-making.

Quality management

Quality Management helps your business objectives become manufacturing reality, with holistic performance management for compliance management issues. Ensure consistent quality in your products, with real-time trends, statistics, and notifications to control quality levels.

Production management

Production management supports full traceability of individual products through every step of the manufacturing process, allowing for auditable genealogy and production reporting. Control product flow between equipment, create product genealogy reports and reduce excess inventory.

Batch analysis

Increase the overall quality and consistency of products and enable a better understanding and control of variation in both new and existing batching applications. Present a comprehensive picture of batch operations in the context of the overall manufacturing facility.

Compare your recent batches with your ideal golden batch. Batch Analysis works hand-in-hand with our Batch Execution module. The S-88-based model defined at the control level is automatically made available at the MES level.